What aluminum is used for CNC?

Views: 388 Update date: Jun 28,2024

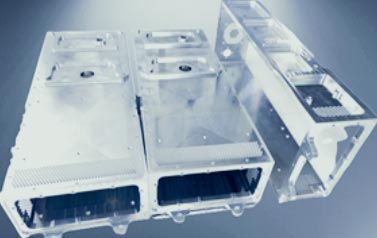

Aluminum is a popular material for CNC (Computer Numerical Control) machining due to its excellent machinability, lightweight nature, and resistance to corrosion. Various aluminum alloys are used in CNC machining, each offering different properties that make them suitable for specific applications. Here are some of the most commonly used aluminum alloys in CNC machining:Aluminum 6061:

Properties: High strength, good corrosion resistance, excellent machinability, and good weldability.

Uses: Aerospace components, automotive parts, bicycle frames, and general-purpose applications.

Aluminum 7075:

Properties: Very high strength, less corrosion resistance compared to 6061, good machinability, and less weldability.

Uses: Aerospace and military applications, high-stress components like gears and shafts.

Aluminum 2024:

Properties: High strength and fatigue resistance, poor corrosion resistance, and difficult to weld.

Uses: Aerospace structures, military equipment, and applications requiring high strength-to-weight ratios.

Properties: Excellent corrosion resistance, good weldability, and high strength.

Uses: Marine applications, pressure vessels, and cryogenic applications.

Aluminum 6063:

Properties: Good strength, excellent corrosion resistance, and good machinability.

Uses: Architectural applications, window frames, and irrigation tubing.

Aluminum 5052:

Properties: Good corrosion resistance, moderate strength, and good formability.

Uses: Marine environments, fuel tanks, and pressure vessels.

These alloys are selected based on the specific requirements of the CNC machined part, including the necessary mechanical properties, corrosion resistance, and ease of machining.