New product 3D printing Verification

Time is going so fast, and the world is developing as well as technology upgrading so fast too, 3D printing is becoming one of the best prototyping way for new product verification. Sanwo is developing and seeing the fast-changing of 3D printing process from the pass 10 years and keeping pace with the times on 3D printing technology. Sanwo provide Rapid 3D printing for your new product development.

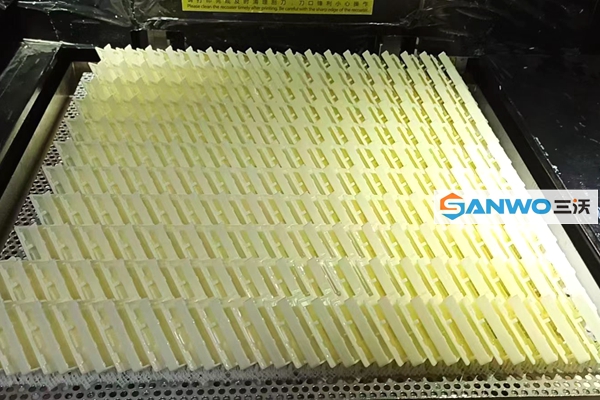

when Sanwo first contact rapid prototyping 10 years ago, For appearance prototype product verification, SLA was the best 3D printing services in the world , and the material for SLA was limited, only one kind of fragile, weak, opaque photosensitive resin material available. And for functional prototype assembly test, SLS was the best 3D printing services in the world that time, material stronger but very rough as it was only white PA powder that hard to get any secondly finish.

And then someday, 3D printing suddenly became a big world overnight. Some client start to using FDM, PLA for it own functional testing, which were faster but lower in quality. And at that time compared to Traditional CNC machining, the product accuracy, material property and appearance still mess, so that we all did not believe the 3D could make the prototype better compared to CNC machining. And as the material cost was high and limited on 3D printing, we did not believe that 3D printing could be competitive to vacuum casting.

Time flies and technology upgrading, 3D printing one day had the translucent material when the opaque material was only the option, though it shows not good, it is a very pretty, it is pretty good progress that 3D printing had made.

Right now, the Clear material is becoming more clear that means CNC machining high hand polish expensive prototype works will be replace soon one day in the coming future.

Today, 3D printing SLA has it own tough material which is the same property as CNC ABS material, for most of the small structure that hard to made by CNC, such as the electronic device shells, which is light, complex, SLA makes the prototype faster and even competitive to Urethane casting.

As well as the SLS PA material, the original white PA was strong enough for the functional parts, and there is one kind of HP PA 12 that Sanwo used for the SLS functional parts which present very much strong close to metal.