Exploring the Benefits and Process of Sheet Metal Prototyping in Modern Manufacturing

Understanding Sheet Metal Prototyping

Sheet metal prototyping is an essential step in the manufacturing process, allowing businesses to create accurate, cost-effective, and functional prototypes. By using this technique, companies can test designs, troubleshoot potential issues, and improve overall product performance before moving to full-scale production. This article delves into the importance of sheet metal prototyping, its benefits, and the processes involved.

What is Sheet Metal Prototyping?

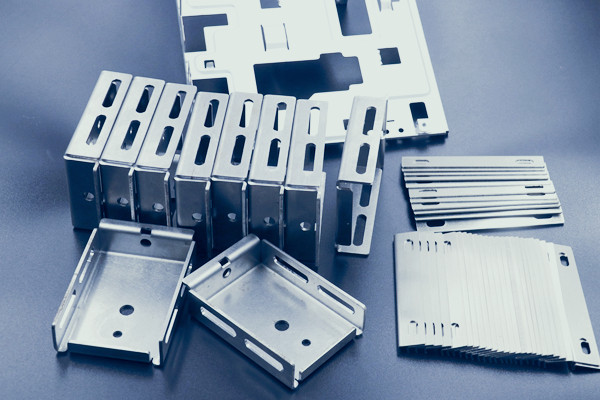

Sheet metal prototyping involves creating a preliminary model or sample of a product from sheet metal, which is a thin, flat piece of metal. The prototype serves as a test version of the final product, enabling designers to evaluate form, fit, and function before mass production.

Benefits of Sheet Metal Prototyping

Prototyping with sheet metal offers numerous advantages, such as:

· Cost Efficiency: Prototypes are often cheaper to produce than full-scale models.

· Faster Time-to-Market: Rapid prototyping speeds up the development process, allowing quicker iterations.

· Design Flexibility: It’s easier to make changes to sheet metal prototypes based on real-world testing.

· High Accuracy: Sheet metal is a durable material, providing prototypes that closely match the final product.

The Sheet Metal Prototyping Process

The process of creating sheet metal prototypes generally involves the following steps:

Design: The initial design is created using computer-aided design (CAD) software. This step ensures that the prototype will be accurate and functional.

Material Selection: The appropriate type of sheet metal is selected based on the project’s requirements (e.g., steel, aluminum).

Cutting and Shaping: The sheet metal is cut, bent, or formed into the desired shape using tools like lasers, punches, or presses.

Assembly: Once the pieces are shaped, they are assembled into the prototype, often requiring welding, riveting, or fastening.

Testing and Evaluation: The prototype undergoes rigorous testing to evaluate its performance and identify any necessary improvements.

Why Sheet Metal Prototyping is Crucial for Manufacturers

Sheet metal prototyping is a crucial tool for manufacturers looking to optimize product designs and streamline production. By identifying design flaws early in the process, companies can save money, reduce waste, and ensure high-quality products. This process also provides a better understanding of material properties, helping to determine the best solution for production needs.

Conclusion: Embracing the Power of Sheet Metal Prototyping

In conclusion, sheet metal prototyping is an invaluable tool that empowers manufacturers to innovate while reducing risks and costs. By leveraging the benefits of rapid prototyping, businesses can achieve high-quality results, accelerate product development, and maintain a competitive edge in the market.