Pressure Die Casting Service

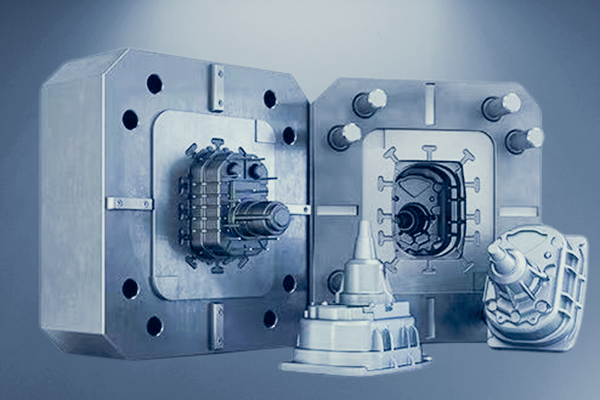

Pressure die casting is a metal volume production manufacture process using a mold and convert the molten liquid metal material in shape. At Sanwo rapid we offer a complete range of pressure die casting services including die and tool making, Material options, metal die casting, secondly machining, post-finish treatment and pre-shipment inspection. Our rich experience, professional service, fast lead time and unbeatable price is our confident in metal volume production dies casting industry.

Aluminum Die Casting

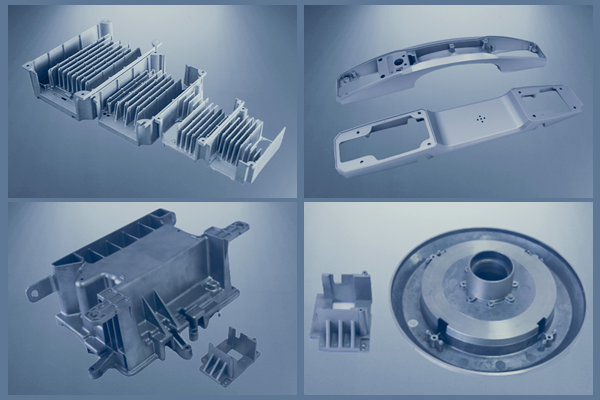

Aluminum Die Casting

Aluminum Die Casting is the most consumed and common metal product manufacture process, it is applied to big volume Aluminum production surpass the volume from CNC Aluminum machining and cost reduce. Product for Aluminum Die Casting required wall thickness around 2-8 mm and thickness difference on the same part lower than 3mm, tolerance for Aluminum alloy is CT5-7

Material options and post finish

| MATERIAL | FINISH |

|

Aluminum alloy: ADC10; ADC12; A380; A384; A386; A390 |

Beadblasting; anodized; painting; plating; powder coating |

|

Magnesium alloy: AZ31B, AZ91D |

Beadblasting; painting; plating; powder coating |

|

Zinc alloy: Zamak 3; Zamak 5 |

Beadblasting; painting, plating, powder coating |

Aluminum Extrusion die

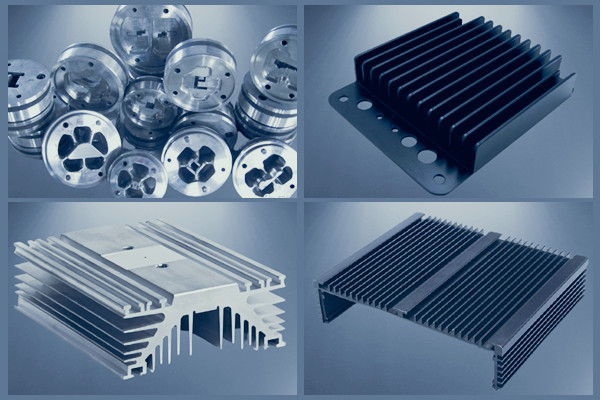

Aluminum Extrusion die

Aluminum Extrusion die is one of the prototypes and low volume manufacturing process in which the heated aluminum Alloy mostly AL6063 or AL 5052 is pushed through a steel die of the desired design profile. according to the shape different, there are some categories in sanwo rapid Aluminum Extrusion die, such as Aluminum Angles and heat sinks; Aluminum round tubes and square pipes and Aluminum Rails, slides and Tracks.