Benefits & Application of 5 Axis Milling Services

Views: 595 Update date: Apr 04,2023

Milling is a process of removing material from a workpiece using a rotating cutting tool. It's a highly versatile manufacturing process that can be used to create a wide variety of parts and products. While traditional milling machines are capable of 3-axis machining (X, Y, and Z axes), 5-axis milling services offer greater flexibility and precision.In this blog, we'll explore 5-axis milling services and their benefits.

What is 5-Axis Milling?

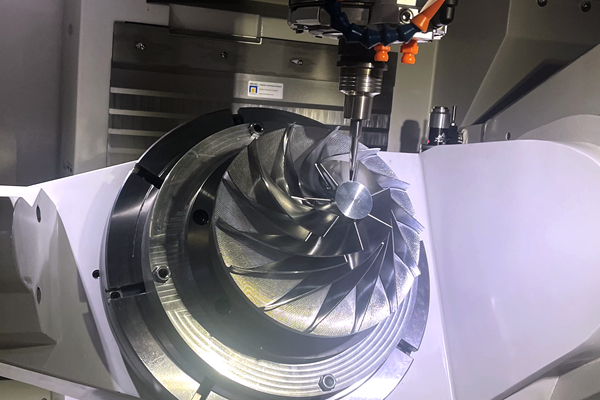

5-axis milling is a machining process that involves moving a cutting tool along five axes to create complex shapes and parts. The five axes include X, Y, and Z axes, as well as two additional rotational axes, typically labeled A and B.In a 5-axis milling machine, the workpiece is mounted on a rotating table that allows for a range of movements. The cutting tool can move along all five axes, allowing for greater flexibility and precision in the machining process. This means that complex geometries and intricate shapes can be machined with ease, reducing the need for additional processing steps.

Benefits of 5-Axis Milling Services

1. Greater Precision

One of the most significant benefits of 5-axis milling is the increased precision it offers. With the ability to move the cutting tool along five axes, the machine can create more complex geometries with greater accuracy. This means that parts and products can be machined with tighter tolerances and more precise details.2. Reduced Setup Time

5-axis milling services can also help reduce setup time. Because the machine can move along multiple axes, it can access different sides of the workpiece without needing to reposition it. This can help to reduce the number of setups required, which in turn can speed up production times and reduce costs.3. Greater Flexibility

Another advantage of 5-axis milling is the greater flexibility it offers. The machine can create complex shapes and geometries that would be difficult or impossible to achieve with traditional 3-axis milling. This means that a wider range of parts and products can be machined, allowing for greater creativity and innovation in the design process.4. Improved Surface Finish

5-axis milling can also help improve the surface finish of machined parts. With the ability to move the cutting tool along multiple axes, the machine can create more complex shapes with smoother transitions between surfaces. This can result in a more consistent and aesthetically pleasing surface finish.5. Reduced Production Costs

Finally, 5-axis milling services can help to reduce production costs. With the ability to machine complex shapes and geometries in a single setup, the need for additional processing steps is reduced. This can help to streamline the manufacturing process, reduce lead times, and ultimately lower costs.Applications of 5-Axis Milling

5-axis milling services are used in a wide variety of industries and applications, including aerospace, automotive, medical, and more. Some specific applications include:Creating complex aircraft parts with intricate shapes and contours;

Machining automotive components with tight tolerances and precise details;

Creating medical implants and prosthetics with customized shapes and sizes;

Machining molds and tooling with complex geometries and features.